Key Pumping Terms for New & Expanding Businesses

September 13, 2021

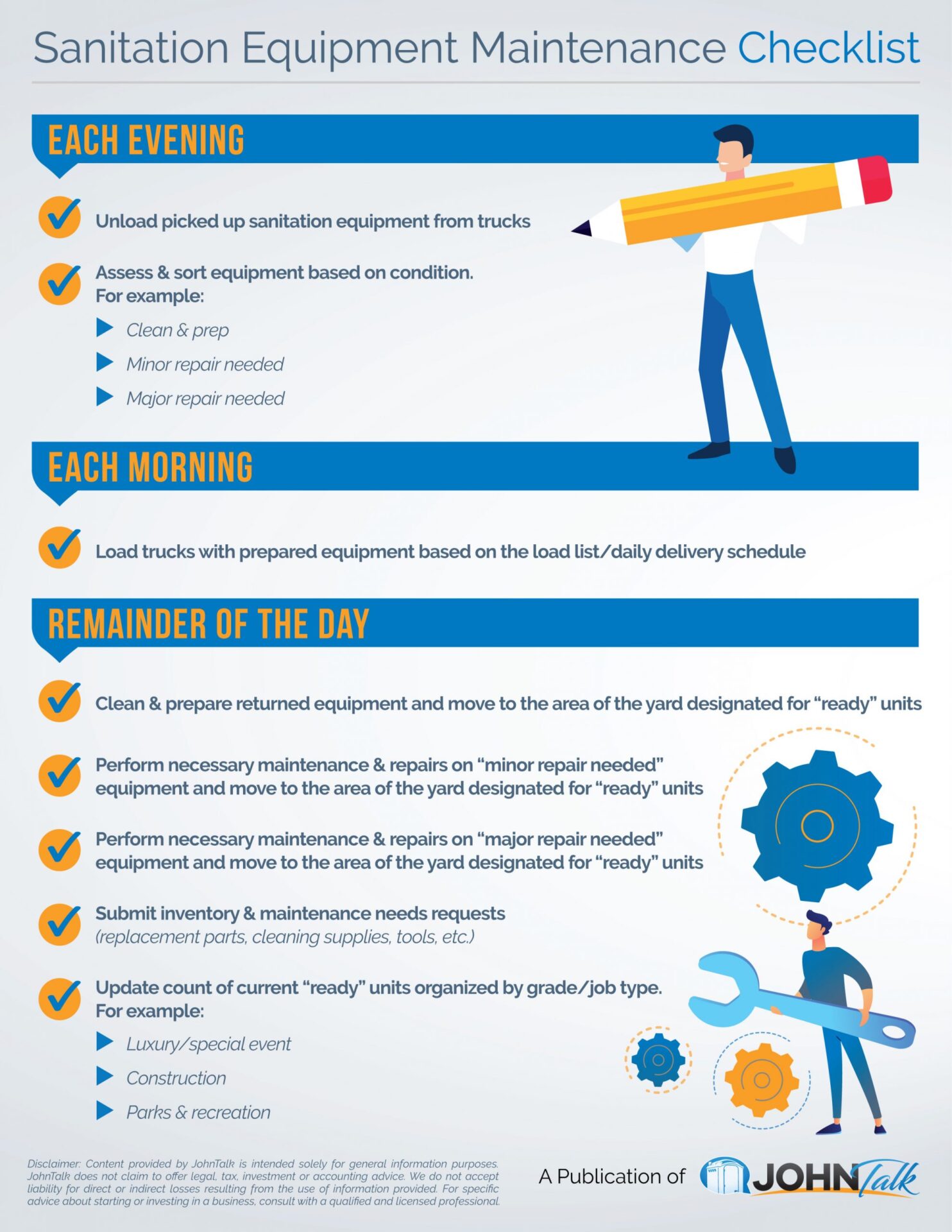

INFOGRAPHIC: Sanitation Equipment Maintenance Checklist

September 27, 2021Portable restroom operators rely on accurate inventory counts to make decisions about parts and equipment purchases. This information helps you prioritize maintenance tasks and respond to customers wanting rentals.

However, long lead times and supply deficits make managing your inventory much more challenging. This is in addition to the challenge of ongoing labor shortages that have impacted PROs across the country.

Typical inventory best practices include using software to automate purchase reminders and deploying sensors to track assets in the field. But, there are other steps you can take to improve inventory visibility. Use the following tips and tactics to navigate today’s inventory challenges.

Achieve Real-Time Inventory Visibility

Knowing what inventory you have in the yard, shop, and field is vital for insurance, maintenance planning, and excellent customer experiences. While you may use stock checklists or radio-frequency identification (RFID) tags to note locations, it’s not a fail-safe method.

Manual data entry errors may result in the over or undercount of inventory. In addition, units may be in various states of repair. These details are essential when a customer calls needing a unit.

Many PROs have turned to cloud-based software to gain real-time visibility, as it’s one of the best ways to track inventory. These tools come with mobile applications, so you and your team can view stock levels and asset locations from anywhere and on any device with an internet connection.

Prioritize Small Parts Management

A few years ago, getting a new part or toilet was simply a matter of placing the order. Today, there’s a longer delay in getting units, partially due to plastic shortages and rising costs in plastic manufacturing.

Therefore, managing your inventory successfully now includes always having the parts to repair your assets on hand and possibly keeping units in the field longer than you previously would have. If you haven’t previously tracked small parts for different toilet and sink models, now is the time to do so.

While you don’t want to overstock expensive parts with limited purposes, you should be doing frequent equipment assessments to predict when you’ll need to replace larger parts and order accordingly.

Get the JohnTalk “ALL-ACCESS PASS” & become a member for FREE!

Benefits Include: Subscription to JohnTalk Digital & Print Newsletters • JohnTalk Vault In-Depth Content • Full Access to the JohnTalk Classifieds & Ask a PRO Forum

Predict Asset Repairs and Replacement Needs

So, how do you know when to add new toilets to your inventory and when to repair them? Again, your inventory software can provide insights. Many tools support automated maintenance schedules that are time- or usage-based.

Additionally, PROs can create reports by filtering assets based on age, use, or repair status. This gives you a general overview of the age of your equipment, how many need repairs, previous maintenance history, and usage amounts.

By inputting the average lifecycle for your assets, you can derive insights from your data to predict when you’ll need to buy new toilets or equipment or verify if you’re maintaining it at the right frequency.

Use Best Practices for Managing Your Inventory

Inventory management is difficult when faced with supply, logistics, and manufacturing disruptions. These instances require PROs to closely monitor existing stock and assets to ensure you order inventory in time.

By using an inventory management system and being diligent about keeping small parts in stock, you can overcome current hurdles and guarantee you have everything needed to run your business and serve your clients.

Looking to Take Your Portable Restroom Business to the NEXT LEVEL? Download our FREE Guide: “Your Guide to Operating A Portable Restroom Business.”

Thinking About GETTING INTO the Portable Restroom Industry? Download our FREE Guide: “Your Guide to Starting A Portable Restroom Business.”