Financing Big Purchases

December 11, 2023

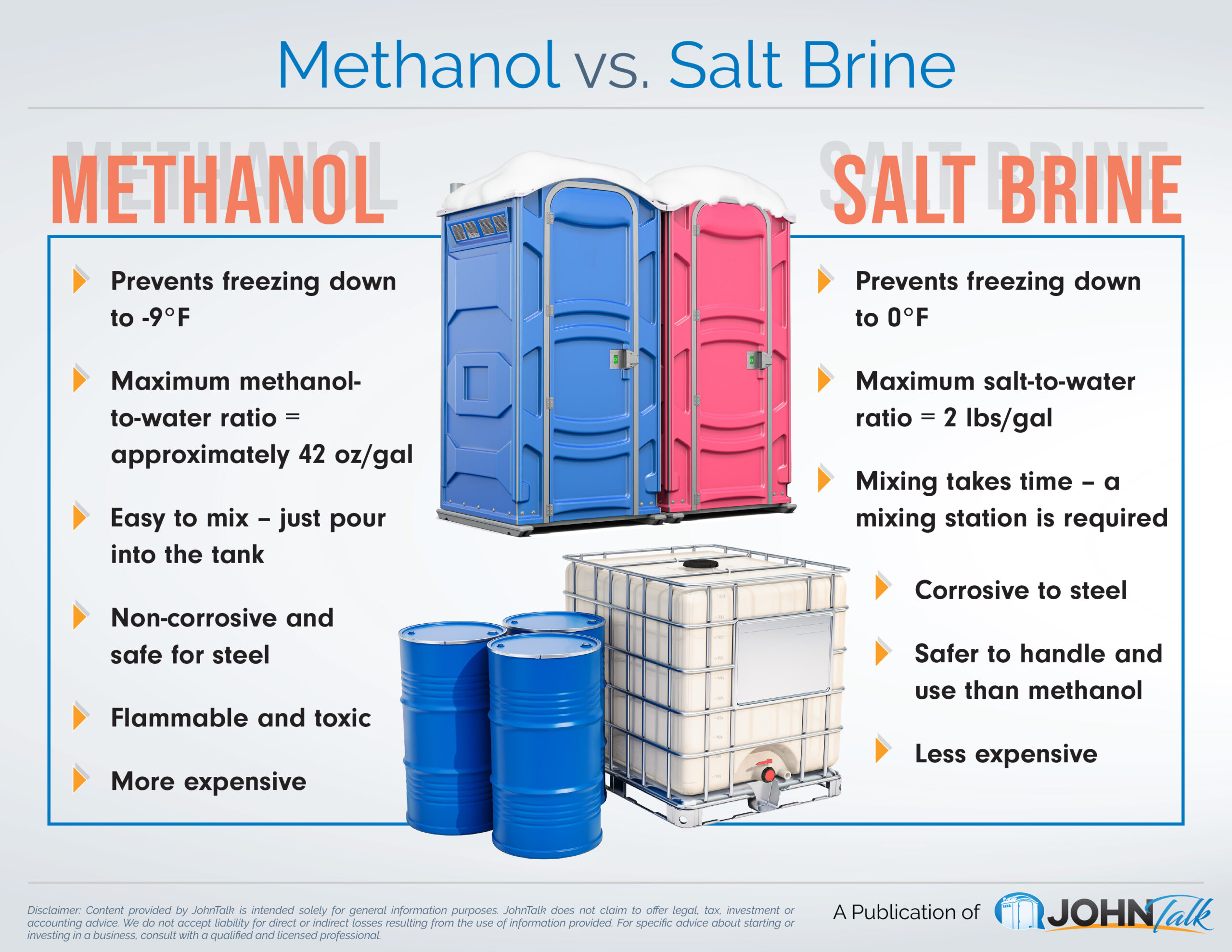

INFOGRAPHIC: Methanol vs. Salt Brine

December 18, 2023

Photo courtesy Jacques Levesque, Aroma Vac Septic Services

Estimating a work truck’s lifespan isn’t an easy feat. Most free industry data is geared toward consumers and light-duty use. And nearly every PRO has a manufacturer preference, regardless of longevity. Indeed, the lifespans of identical trucks can vary slightly based on routes and drivers.

Although no one agrees on one standard for PROs, you can follow best practices when replacing trucks. Learn how to spec your vehicles and standardize your fleet while collecting data for better purchasing decisions.

Spec Your Trucks Correctly to Extend Lifespans

The right equipment combination for your job sites and routes can help your trucks last longer and perform better. On the other hand, if you frequently go above the vehicle’s rated payload, you could face early drivetrain failure and suspension issues. While Class 6 models typically run longer than Class 5, a 550 truck navigates rougher terrains better than dual-axle models.

Start by learning the OEM requirements for tow and load capacity. Factor in your tank material and size. Then, evaluate your service area to estimate fuel efficiency and longevity. Remember, every component counts, from tire size to the cab-to-axle (CA) measurement.

Consider Standardizing Your Fleet

Fleet standardization can reduce inventory and labor costs, making vehicle maintenance easier and extending their lifespan. Some PROs use one manufacturer, whereas others use one setup like the same cab, engine, chassis, and transmission or engine, transmission, and tires. Your service technicians may have a preference based on their familiarity with an engine. In addition, industry data and your fleet’s maintenance records may help you choose the most reliable work trucks.

The primary way standardizing your fleet improves longevity is through data. When you have a couple of models with the same transmission, weight, and motor, you can compare their performance. For instance, if the trucks travel similar routes, but one consistently uses more fuel than another, you will catch the issue early and inspect the situation.

Get the JohnTalk “ALL-ACCESS PASS” & become a member for FREE!

Benefits Include: Subscription to JohnTalk Digital & Print Newsletters • JohnTalk Vault In-Depth Content • Full Access to the JohnTalk Classifieds & Ask a PRO Forum

Increase Longevity by Collecting Data

It’s challenging to predict the expected lifespan of equipment. However, studies show that preventative maintenance and driver use impact longevity. Increasing visibility into these aspects helps portable restroom operators identify and correct problems. The data also informs future purchasing decisions.

The easiest way to get accurate odometer readings and driver safety data is to use telematics devices with fleet management software. Some solutions integrate with routing platforms for enhanced analytics and insights.

Consider tracking the following fleet metrics:

- Route efficiency

- Preventative maintenance on-time completion rate

- Scheduled versus unscheduled service

- Inspection completion rate

- Mileage and hours

- Fuel consumption and miles per gallon (MPG)

- Average miles per driver

- Cost per mile

- Telematics data like diagnostic trouble codes (DTC)

- Total cost of ownership (TCO)

Maximizing Fleet Longevity

When it comes time to spec a new work truck, don’t rush. Look at the data and consider how it fits into your long-term plan. Every PRO you talk to will have a preference, whether gas or diesel, Ram or Ford, and aluminum or stainless steel tanks. The bottom line is that timely preventative maintenance, properly spec’d trucks, and a thorough safety training program can improve the lifespan of your fleet.

Looking to Take Your Portable Restroom Business to the NEXT LEVEL? Download our FREE Guide: “Your Guide to Operating A Portable Restroom Business.”

Thinking About GETTING INTO the Portable Restroom Industry? Download our FREE Guide: “Your Guide to Starting A Portable Restroom Business.”