The CARES Act & Portable Sanitation

May 11, 2020

INFOGRAPHIC: How to Make Homemade Masks

May 25, 2020With an uptick in supply use and an increased need for handwashing stations, PROs have been rushing to place orders. You need more soap, sanitizer, and toilet paper. But when you go to place an order, you’re told it’ll take weeks or months to receive new products. What gives?

Unfortunately, the impact of the COVID-19 pandemic has resulted in longer lead times for many products. As an operator, it’s hard to be patient when you need critical supplies and have customers who depend on you. This article explores the effects on the industry and will help you learn what you can do to adapt to longer lead times.

Demand and Safety Protocols Increase Lead Times

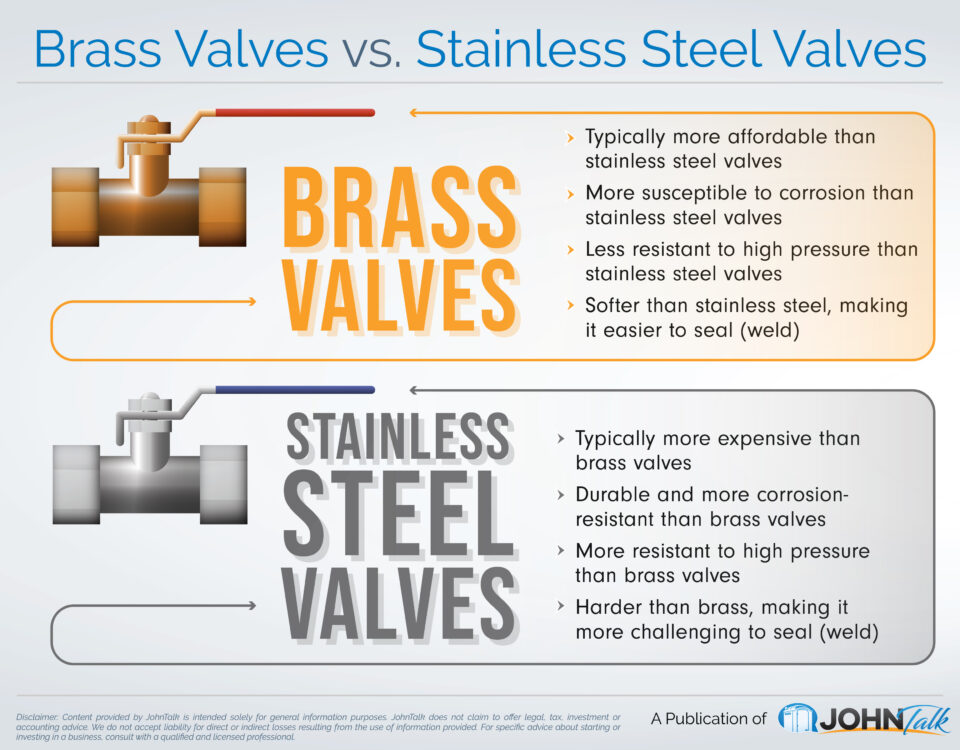

While items like sinks and chemicals like hand sanitizer are frequently shipped in large quantities, the sheer numbers of orders rose dramatically as more businesses stepped up to provide communities with portable sanitation services. Increased cleaning services require more products and supplies. Items like sinks, once a fantastic upsell, are now a top priority for customers.

Although many suppliers ramped up operations to meet the demand, they’re also facing supply chain issues. Obtaining ingredients for various manufacturing processes is taking longer than usual and may depend on how geographic regions are affected.

Many businesses are juggling workloads while implementing safety protocols to protect employees. In some cases, this changes the workflow in the factory and requires an adjustment period to get workers up to speed while producing items at a high volume.

Get the JohnTalk “ALL-ACCESS PASS” & become a member for FREE!

Benefits Include: Subscription to JohnTalk Digital & Print Newsletters • JohnTalk Vault In-Depth Content • Full Access to the JohnTalk Classifieds & Ask a PRO Forum

Ways PROs Can Adjust to Longer Lead Times for Supplies

Although you can sympathize, you still need supplies and equipment. Start by talking with your suppliers. Find out which items have longer lead times and ask if alternative products are available. Then, take steps to lessen the impact on your business.

Audit your supplies and current equipment. Look at previous year orders to see which supplies are in more demand now. Use your data to make predictions on what you’ll need for the next 30 to 90 days.

Place orders to build up your inventory. Although money is tight, building up your stock is a way to protect yourself from supply chain issues. Determine which products have longer lead times. Consider ordering and paying for these products early to secure your product.

Diversify your suppliers by choosing places in different geographic regions. Diversification and relationships with multiple suppliers may help you procure items quickly. Certain areas may have an outbreak that slows operations, so invest time in finding suppliers in different parts of the country.

Get creative with supplies. While you won’t be making toilet paper anytime soon, you may opt to make sanitizer or find alternative products. We’re also seeing PROs constructing sanitizer distribution and hand wash stations. While this is a temporary fix, customers will appreciate your innovation.

A Bump in the Road for Portable Sanitation Supplies

Going forward, the supply chain will eventually normalize. Until then, procuring items requires a bit more planning. Keep the lines of communication open with your suppliers and customers. Tighten operations by assessing inventory needs more frequently. Then, look for creative ways to reduce the impact on your company and clients.

Looking to Take Your Portable Restroom Business to the NEXT LEVEL? Download our FREE Guide: “Your Guide to Operating A Portable Restroom Business.”

Thinking About GETTING INTO the Portable Restroom Industry? Download our FREE Guide: “Your Guide to Starting A Portable Restroom Business.”