How to Monitor the Quality of Your Service Technicians’ Work

July 15, 2019

Succeeding with Special Events

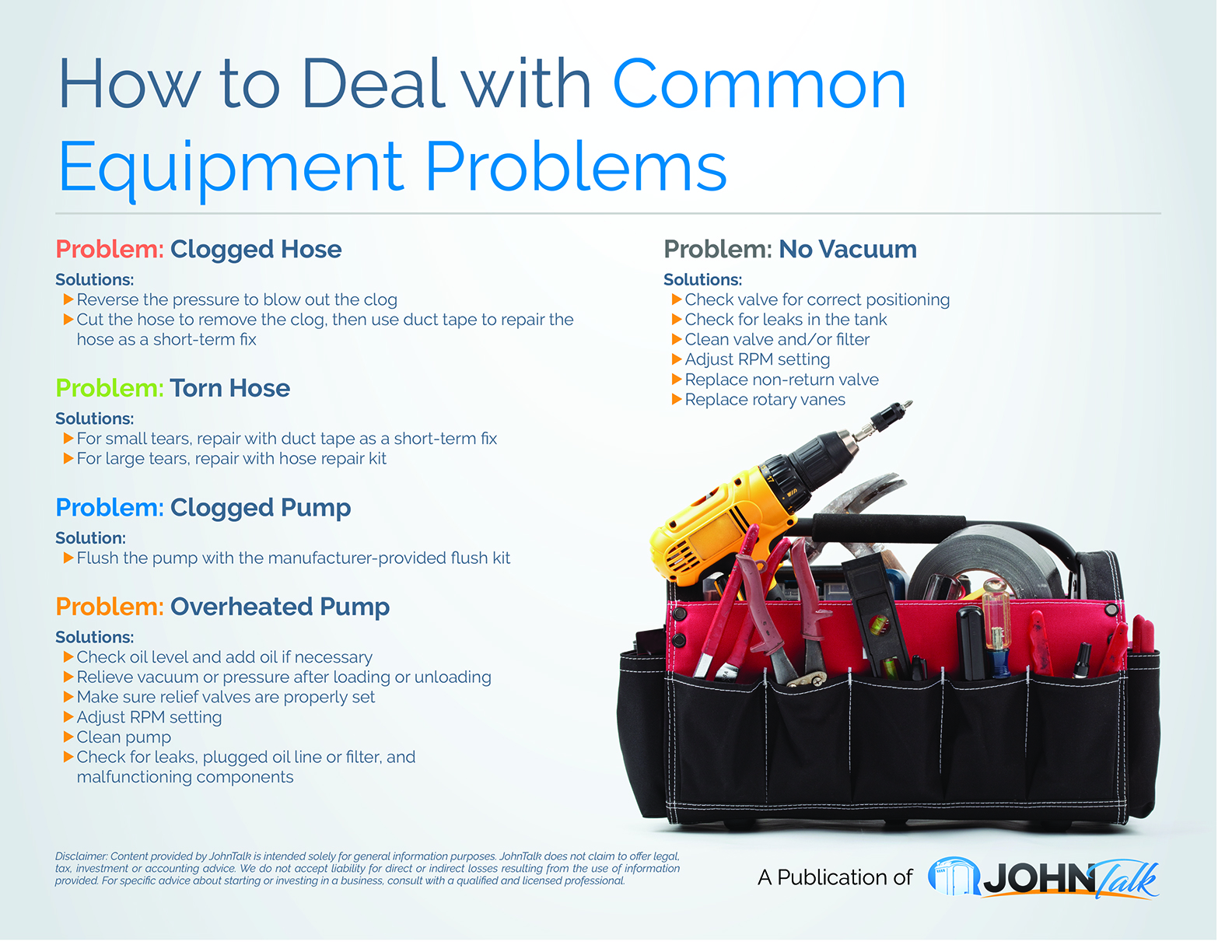

July 29, 2019Portable restroom operators need properly functioning equipment to stay on schedule and get the job done. Unfortunately, it’s not uncommon for little issues to pop up once in a while. For these common equipment problems, preparation is key.

This infographic lists some of the most common equipment problems PROs face on the job, along with potential solutions. Hopefully, these tips will help you get back on track quickly.

Like this infographic? Share it with your friends and colleagues!

Get the JohnTalk “ALL-ACCESS PASS” & become a member for FREE!

Benefits Include: Subscription to JohnTalk Digital & Print Newsletters • JohnTalk Vault In-Depth Content • Full Access to the JohnTalk Classifieds & Ask a PRO Forum

Looking to Take Your Portable Restroom Business to the NEXT LEVEL? Download our FREE Guide: “Your Guide to Operating A Portable Restroom Business.”

Thinking About GETTING INTO the Portable Restroom Industry? Download our FREE Guide: “Your Guide to Starting A Portable Restroom Business.”

How to Deal with Common Equipment Problems

Problem: Clogged Hose

Solutions:

- Reverse the pressure to blow out the clog

- Cut the hose to remove the clog, then use duct tape to repair the hose as a short-term fix

Problem: Torn Hose

Solutions:

- For small tears, repair with duct tape as a short-term fix

- For large tears, repair with hose repair kit

Problem: Clogged Pump

Solution:

- Flush the pump with the manufacturer-provided flush kit

Problem: Overheated Pump

Solutions:

- Check oil level and add oil if necessary

- Relieve vacuum or pressure after loading or unloading

- Make sure relief valves are properly set

- Adjust RPM setting

- Clean pump

- Check for leaks, plugged oil line or filter, and malfunctioning components

Problem: No Vacuum

Solutions:

- Check valve for correct positioning

- Check for leaks in the tank

- Clean valve and/or filter

- Adjust RPM setting

- Replace non-return valve

- Replace rotary vanes