INFOGRAPHIC: What’s the Best Tank Material?

March 13, 2018

How to Bid Contracts

March 15, 2018

Photo courtesy Robinson Vacuum Tanks

Let’s take apart a pumper truck.

Hold the wrenches! We mean let’s look at the various aspects and features of the portable sanitation service truck, commonly called the pumper truck. The basic truck is a vehicle that carries a vacuum pumping system that enables the PRO (portable restroom operator) to suction waste from a portable toilet into a tank on the truck. A water compartment in the tank allows the operator to wash the toilet and replenish the fresh water in the porta-potty. A common option on pumper trucks is a carrier to transport the units.

Like you, your truck is an everyday worker. The truck is your work partner, your heavy lifter. Over time, you will become familiar with every aspect of your own truck (and we hope, eventually, your fleet of trucks).

Today’s trucks are well-made, long-lasting vehicles that carry a combination of heavy-duty equipment and sophisticated technology. Your pumper truck is the single most expensive piece of equipment in your business, and you want to use it for a long time, so when buying or leasing your truck, new or used, take your time to make the right decision.

We reviewed the truck models produced by the major manufacturers of pumper trucks to see what features they highlight. This list will give you a good starting point to compare manufacturers:

- Robinson Vacuum Tanks – https://robinsontanks.com/

- Amthor International Tank Trucks – https://amthorinternational.com

- Best Enterprises, Inc. – www.bestenterprises.net

- Crescent Tank – www.crescenttank.com

- FlowMark – https://flowmark.com

- KeeVac Industries, Inc. – www.keevac.com

- Pik Rite, Inc. – www.PikRite.com

- Satellite Industries – www.satelliteindustries.com

We recommend that you check out their websites as well as other manufacturers and learn about their products. Compare features, service, parts and warranties. Manufacturers also post informational videos on YouTube. Don’t hesitate to contact the manufacturers if you have additional questions.

An excellent way to compare products in person is by attending the WWETT Show (Water and Wastewater, Equipment, Treatment and Transport), the world’s largest annual trade show for wastewater and environmental services professionals. For more information, go to https://www.wwettshow.com/en/home.html.

The manufacturers will be able to help you find a local distributor in your area. Talk to the dealer about leasing options if that is your choice. You can also check the internet for other dealers in your vicinity.

A Note About Slide-In Units

A slide-in is a completely self-contained portable sanitation unit (vacuum pump, tank, etc.) that fits in a standard, full-size pickup bed or on a trailer. As an inexpensive “starter” or for small-scale operations, a slide-in unit is an economical alternative to the significant financial investment of a pumper truck.

Now, let’s take a closer look at the major components of the pumper truck.

Chassis

The chassis is the solid, basic foundation of your truck. It is the vehicle frame, engine, transmission, suspension, brakes, axles and tires. The chassis of the pumper truck includes the cab — the space where the driver sits. Pumper trucks usually have a conventional cab design, where the driver is seated behind the engine.

Pumper truck chassis are built in makes and models to meet most any need by all the major manufacturers: Chevrolet, Dodge, Ford, Freightliner, Hino, International, Izusu, Kenworth, Mack, Mitsubishi, Peterbilt, Sterling, etc. For example, popular models are the Ford F-550, Dodge Ram 5500 and the Hino 268. The portable sanitation equipment is added to the chassis by the pumper truck manufacturers.

So, when buying or leasing a truck, there are a lot of options to choose from. Of course, you may simply prefer one brand of truck over the others. Many operators make a significant investment by having their truck custom-built to their specifications, in part so they can choose their own chassis (when ordering a truck, take into account that some chassis require extra lead time to be outfitted with portable sanitation equipment). Others are fine with floor-ready models or economize by buying used.

Whatever your choice, you should tailor the truck to its workload and your budget. Prices of makes and models can vary by thousands of dollars, which is why matching is critical. Don’t buy too much truck or too little truck.

There are many things to consider. Do the roads on your service route have hills? Do you go off-road a lot? Do you want the capacity of a larger tank? You’ll need a heavier transmission. Do you have a lot of customer sites where there is little space to maneuver? Then a tight turning radius becomes an important benefit. Be careful not to underestimate the chassis you will need. A chassis that is too light for its workload can reduce productivity and put excessive wear on the truck.

Fuel economy is often at the top of the list of reasons to buy a particular truck. Fuel is one of the largest expenses of your business. Remember, all those accessories you want (the “bells and whistles”) add weight or consume more power and cut down your mpg. Once you own your truck, tracking the truck’s operating expenses on a cost-per-mile basis will help determine how fuel impacts your business.

But for many operators, the most important factor in choosing a pumper truck isn’t cost, miles per gallon, brand or accessories. It’s how easy it is to have the truck serviced. Because if your truck breaks down, your business breaks down! When your truck needs repairs, you want service that is completely trustworthy, nearby, experienced with your brand and gets you back on the road quickly. Talk to your local distributors about their after-sales service, as well as repair shops in your area.

Cab

The cabin is part of the chassis, and it will be your home away from home for several hours every day. Consider comfort and safety. Is it easy to get in and out? Is it comfortable and roomy? Do you like the configuration of the dashboard? How is visibility? Will it help to have a backup camera? What amenities do you want – sound system, air conditioning, power seats, power windows, cup holders? Some operators prefer a stripped-down cab that lowers the initial purchase price.

You might already be familiar with another option. Many pumper truck models offer upfitter switches. These switches connect to the electrical system of the truck and allow you to control your pump and other equipment from the cab.

GVWR

An important consideration is the gross vehicle weight rating (GVWR) of your truck. GVWR is a rating of the maximum operating weight of a vehicle and is used to specify weight limitations and restrictions. Vehicles over 6,000 pounds can’t be driven on some roads. Commercial vehicles over 8,500 pounds are required to have insurance. Vehicles that weigh 26,001 pounds or more generally require a Commercial Driver License (CDL) or a Non-Commercial Class “A” or “B” license. Manufacturers list the GVW in their specs.

GVW is the total weight of the vehicle and the load – including the driver, units, equipment and the weight of the waste and water you are hauling. Water weighs 8.4 pounds per gallon (waste is a little more), so a full tank will add thousands of pounds to vehicle weight.

Keep the GVWR in mind when adding accessories. You can buy pumper trucks that don’t require a CDL to operate, but adding accessories or swapping out the factory-installed tank with a larger tank (carrying a heavier load) can cause your truck to exceed its GVWR. There can be large fines for violating state laws on truck weight. For an in-depth review of all state laws involving truck size and weight limit, go to https://ops.fhwa.dot.gov/freight/policy/rpt_congress/truck_sw_laws/index.htm.

Get the JohnTalk “ALL-ACCESS PASS” & become a member for FREE!

Benefits Include: Subscription to JohnTalk Digital & Print Newsletters • JohnTalk Vault In-Depth Content • Full Access to the JohnTalk Classifieds & Ask a PRO Forum

Fuel

Pumper.com notes in a 2017 article (“Making Sense Of Alternative Fuel Choices”) that while most pumper trucks run diesel, gasoline is a workable option. Gas is available for Class 7 (33,000 lbs. GVWR) and smaller and is best suited to low-mileage applications of 25,000 miles or 600 hours or less per year.

Advantages of gas:

- Total cost of ownership is less due to the reduced purchase price and maintenance costs

- Gas is readily available

- No special requirements in handling fuel

- Simple, reliable emission system

- Reduced downtime; many repair shops

Disadvantages:

- Requires higher rpm to generate torque

- Less mpg

- More frequent maintenance

- Limited PTO applications

- Not environmentally friendly

Tank

The storage tank, with all its features, options, and the equipment and accessories that go with it, makes up a complex system that is engineered to make servicing portable toilets and storing and dumping waste as convenient and efficient as possible.

Your budget, the size of your business and the length of your route should be the main reasons you choose certain tank options over others. With many tank systems available from several leading manufacturers, you should be able to find the ideal one.

To begin, let’s look at the tank itself.

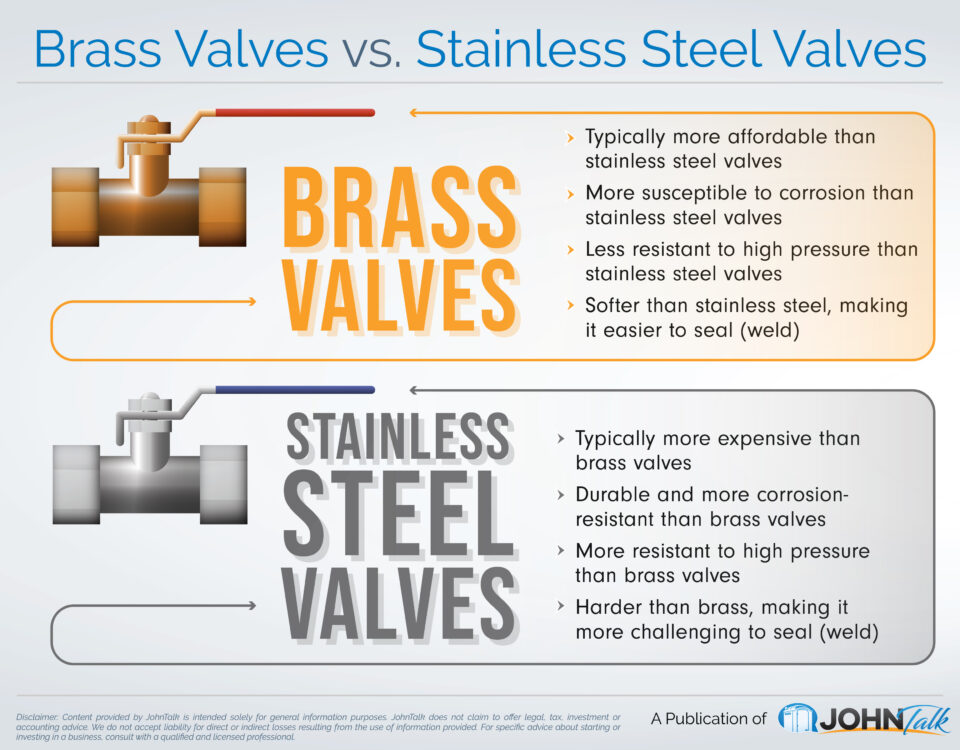

Tanks are made from three materials: carbon steel, stainless steel and aluminum. Each type has excellent advantages, as well as certain drawbacks.

Carbon Steel

Pros:

- Durable, lasts a long time

- Good price value

Cons:

- Heavy weight

- Prone to rusting and pitting, requiring more maintenance

Carbon steel tanks provide dependable performance at a good price. Manufacturers add a coating inside the tank – commonly an epoxy lining or magnesium anodes – to prevent corrosion and lengthen tank life. Due to weight, tanks tend to be smaller and hold less. Weight can affect the maneuverability of the truck.

Stainless steel

Pros:

- Most durable and longest lasting

- Won’t rust

Cons:

- Weighs the most

- Costs the most

Although a stainless steel tank will add to your initial purchase price, the tank is durable enough to outlast the truck itself. Again, the weight should be considered for its effect on capacity and maneuverability.

Aluminum

Pros:

- Lightest weight of the three

- Doesn’t rust

Cons:

- Shortest life expectancy

- Shows wear easily

The operator can have a tank with greater capacity and still stay under the 26,001 lbs. GVW for vehicles that don’t require a CDL to drive. Larger capacity means you don’t have to dump your load as often, saving you more time. Lighter weight improves fuel efficiency.

HDPE Tanks

A new innovation in the industry is a vacuum tank made of high-density polyethylene (HDPE) instead of steel or aluminum. The tank is lightweight, requires little maintenance, and is rust-proof and corrosion-proof. It can service on average 35 to 40 portable toilets per trip. HDPE tanks are available for slide-in units (see note above about slide-ins).

Tank Load

The tank is placed on the chassis so weight is distributed evenly. Your tanks should have baffles or a baffle system inside. Baffles are partitions that deflect the motion of the fluid (the “surge load” or “slosh load”). Let’s say you have 500 gallons of waste in your tank. At about 9 pounds per gallon, the total weight is about 4,500 pounds. When you start moving, that’s more than two tons of liquid sloshing back toward the rear of the tank. When you brake, the liquid flows toward the front of the tank. When you turn, it flows sideways. The force is hard on your engine, hard on your brakes and hard on your truck. Baffles are a welcome safety and control feature. (However, they do add to truck weight.)

Tank Size

Tank size is an important consideration. There is a great variety of tank sizes. You’ll see tanks as small as 300 gallons and as large as 4,000 gallons. A common tank size is 1,000 to 1,500 gallons, but again, you should size your tank to your needs. How many units will you service? One standard portable toilet has a waste tank volume of about 60 gallons.

Operators are trending toward larger tanks. You gain storage, which means you save time and money making fewer trips to dump sites. But you give up some maneuverability and can expect reduced fuel economy due to the extra weight. Make sure you have enough truck to carry the load but stay within your weight limit. The manufacturer or distributor will work with you to make sure the vacuum pump is properly sized to your tank.

Tank Compartments

- Waste compartment

- Freshwater compartment

Most tanks are divided into two sections – one holds waste and the other holds fresh water – so you can vacuum, refresh and wash the units with one service call. They are offered in many combinations, such as 1,000 gallons (650 waste/350 water), 1,300 (900/400), 1,500 (1,000/500), etc.

A variation is a split freshwater tank for servicing in colder climates. One compartment holds fresh water, and the other holds brine mix (which doesn’t freeze). For example, a 500-gallon water tank is split into two, 250-gallon sections.

Other Tank Features

- Vacuum inlet valve

- Discharge outlet valve

- Manway

- Primary shut-off

- Level indicators

The tank has several built-in access ports.

There is one vacuum inlet valve (usually 2”) on top of the tank and a separate discharge outlet valve (usually 3” or 4”), sometimes called the “dump valve,” on the bottom of the tank. The inlet valve is located on top because you would be fighting pressure trying to get the waste in from the bottom. When emptying the tank, this pressure becomes an advantage. Just open the dump valve, and let gravity do the work!

When cleaning a unit, the pump is set to “vacuum” to suck up the waste and deposit it in the tank through the inlet. To empty the tank, some operators have a pump that can be set to reverse, or “pressure,” to help gravity force out the waste.

Most tanks are manufactured with another access port, called a manway, at the top. Usually about 20” (larger sizes are an option), the manway lets the operator access the inside of the tank for cleaning and repairs. For safety, do not enter the tank unless you’ve been trained in confined space entry.

The primary shut-off is also on top. The shut-off holds a stainless steel float ball. When the waste reaches full, the float restricts air flow to the vacuum so it can’t pump additional waste, automatically preventing accidental overflow and letting the operator know the tank has reached capacity and needs to be dumped.

Level indicators help you estimate how full the tank is. The most common indicators are sight bubbles, which allow the operator to make a visual check of the liquid level. There are usually three, at the bottom, middle and top of the tank. Other options are a sight tube, mechanical gauge and electronic gauge.

You’ll learn to keep an eye on your levels. If you don’t anticipate when the tank will be full, you could be in the middle of a job when the tank reaches capacity and you can’t vacuum anymore. As a result, your hose could still be full of waste, so you’ll have to either dump it back into the unit or wind up that full, heavy hose. And if the wand valve opens, you’ll have waste streaming out. That’s a health, safety and a spill issue all in one.

When operators get waste spilled on them in this manner, we called it being baptized!

Work Station & Accessories

- Side cabinet(s)

- Toolbox(es)

- Hose and hose reel

- Bucket fill/bucket holder

- PTO controls (optional)

- Pressure wash system (optional)

You’re on your route and it’s time to clean the units. Your truck’s workstation is where all the action happens. Your cleaning implements, tools and accessories are organized around the truck tank to give you complete control to vacuum out the toilet holding tank, clean and restock the unit and handle any emergencies or other needs.

The vacuum pump is located here. If the pump is operated with a PTO (power take-off) system, the controls are often here (otherwise, in the cab). Cabinets or compartments for stocking supplies are standard, as is a toolbox. The bucket fill (with bucket holder) is a water tank outlet where you fill your bucket for washing down and refreshing the unit.

The service hose with wand attachment is stored on a hose reel that is most often attached to the side of the tank, or occasionally on the back. The standard hose in the industry is the flexible, crushproof “tiger tail” hose, usually 25 or 30 feet or more in length. Where’s your discharge hose? Many PROs don’t carry one on their truck. Hoses of various diameters are often provided at dump sites, or as mentioned before, operators simply open the discharge valve and let gravity empty their tank.

A common option for your work area is a 1/2” water hose with spray wand (and reel) and pressure wash system used to wash down units. Water pressure is provided by a water pump (usually 12 volt) located near the vacuum pump.

Many truck models offer the convenience of “dual service” – having an inlet, bucket fill and compartments on both sides of the truck. Larger tank trucks may offer a work area with drop-down sections (low to the ground) to make accessing hoses and tools easier.

Pump

The vacuum pump is the powerhouse of your portable sanitation operation.

Pumps generally have a rotary vane design and are either powered by a gasoline engine or a PTO (power take-off) system. PTOs attach to the truck transmission and transfer the power of the engine to the vacuum pump. As mentioned earlier, some pumps can be set to reverse, or “pressure,” to help gravity force out the waste.

If you don’t know a lot about pumps, let the truck manufacturers do the work for you. When you buy a pumper truck built by any of the major manufacturers, it will feature a rugged, high-performance pump that has been properly sized according to the capacity of the tank.

You may prefer to buy a truck with a certain make of pump. There are also manufacturers that will custom-build your truck, allowing you to select the pump of your choice. You can compare specs from pump manufacturer websites, and contact the company or local distributor for technical support. Some of the major pump manufacturers are:

- Masport (masportpump.com)

- NVE (National Vacuum Equipment) (https://natvac.com/)

- Fruitland Manufacturing (fruitlandmanufacturing.com)

- Jurop (https://www.jurop.it/en/home)

- Battioni (https://www.bapag.it/en-US/battioni-pagani-pompe—parma.aspx)

- Moro (http://www.morousa.com/Vacuum-Pumps/)

- Westmoor, Ltd. (Conde pumps) (westmoorltd.co)

- Chandler (https://chandlerequipment.com)

As you gain experience in your business and become more familiar with your equipment, you’ll become an expert in your pump(s). This is valuable knowledge that every PRO should have.

The End-Unit Holder & Rear Hitch

The pumper truck efficiently uses its space right to the very end. In many models, the back end of the truck is mounted with a reinforced 2-unit toilet rack. A few can even hold four. The typical liftgate gives the operator easy access to the units. If you’ll be carrying toilets, store a dolly on your truck. Look for a model that includes a trailer hitch mount if you want to haul even more units.

Many pumper truck models add one more feature – the license plate holder! And don’t forget work lights, because we all know that after you buy the truck you’re likely to be working all hours — day and night!

Looking to Take Your Portable Restroom Business to the NEXT LEVEL? Download our FREE Guide: “Your Guide to Operating A Portable